lattice compression testing|Compressive Behaviour of Additively Manufactured : importer This study proposes a simplified numerical model for analyzing lattice structure compression behavior before failure, incorporating X-ray microcomputed tomography (CT) .

Resultado da 26 de ago. de 2021 · Porta-voz da luta contra o tráfico humano nas redes sociais, a influenciadora e ativista Danny Boggione desenvolve trabalhos .

{plog:ftitle_list}

webJunte-se à Bet55 e libere seu poder de vitória! Inscreva-se agora e aproveite a diversão ilimitada do jogo. Sua segurança é sempre nossa principal prioridade. Por meio de tecnologia de criptografia avançada, suas informações pessoais e fundos serão protegidos ao .

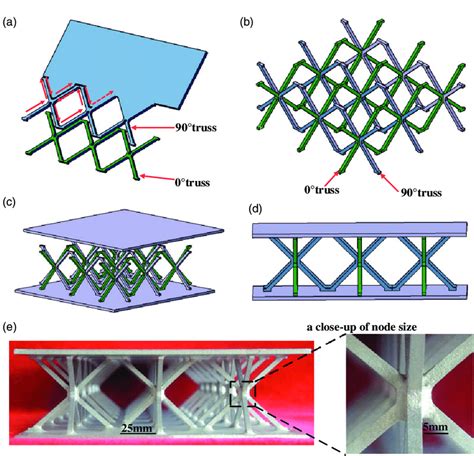

Compression tests were conducted on four types of lattice structures (BCCx, ECC, OTC, and HXC), which were designed to have a 15 % volume fraction. These lattice structures showed hyperelastic bending-dominant behaviors overall, with the OTC lattice also showing a .

The compression tests were conducted in a screw-driven universal testing machine . The review also examines the failure modes/mechanisms of lattices under compression, as well as the impact of lattice geometry (cell size and . In compression tests, lattice structures maintain stiffness even when filled with powder, suggesting minimal effect from the filler material. This paper shows the principles of . The experiment approaches the testing at compression for lattice structures manufactured by SLS from a polyamide plastic. Experimental conditions that were taken into .

This study proposes a simplified numerical model for analyzing lattice structure compression behavior before failure, incorporating X-ray microcomputed tomography (CT) . X-ray micro-computed tomography (μ-CT) is employed to capture the realistic geometrical information of lattice struts. Based on the statistical characteristics, a novel finite .

Simulation of the Compression Testing of Additively Manufactured

Lattice patterns are designed to create lighter and stronger structures for various industrial applications. With progress in additive technology, lattice structure investigations . The pure Vero lattice absorbed the most energy, 5.76 J, and the material withstood the most force in mechanical testing, 10.5 kN in compression, and 840 N in tensile. The pure Vero lattice structure also resulted in the highest acceleration in drop tower impact absorption, 124 m/s 2 , a property very unfavorable for applications such as helmets. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater., 159 (2018) . E9–09(2018), Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International, West Conshohocken, PA (2018)

The lattice coupons are subjected to quasi-static compression testing to evaluate their mechanical properties, with differences shown indicative of changes in the manufacturing process. The work reported here acts as a proof of concept for a low-cost build quality evaluation methodology using lattice coupons and compression testing alone. Figure 10a depicts compression test results for the three Simple Cubic lattice samples versus the FEA model, plotted as the moving plate’s reaction force versus its displacement. The experimental reaction force curves clearly show a linear elastic region up to the first layer collapse beginning at 400–450 N, after which, the force . To conduct the virtual compression test on the model, a fixed displacement was applied to the top surface of the lattice structure up to a strain of 0.045 under quasistatic loading conditions. In contrast, the bottom surface of the lattice model was constrained in the loading direction ( y -axis), and the symmetric boundary condition was . Compression Test at 5 mm per minute. Logan Drake performing his honors research project. #lattice_structure #compression

In this study, the mechanical behavior of Schwarz-P TPMS lattice material under uniaxial compression has been compared for two different polymers – PLA and ABS, at different compression speeds from 5 mm/min to 35 mm/min to obtain a comprehensive picture. . with 50 kN load cell. The compression testing was done at four different rates of .

The paper brings forward the results of a study on the compression test of 28 lattice structures made ofPLA by FDM, with the height of the deposited layer at a pass of Hs = 0.20 mm and 50% filling .The compression test is the most used one to characterize lattice structures due to the majority of their applications where the structures are subjected to this type of load. For example, in the biomedical industry, the compression performance of implants, together with the fatigue life and biocompatibility, is the key factor for selecting the . The stress–strain curves of the lattice structures under quasi-static test are shown in Fig. . Through the quasi-static compression test curve, the critical impact transition velocity of lattice structures from uniform deformation mode to impact deformation mode can be predicted, so that the suitable lattice structure can be selected . Considering the compression test at 200 °C, . This can be attributed also to a lower level of densification at the end of the test of the lattice samples in T6 condition with respect to SR. Considering that T6 treatment needs higher furnace temperatures and longer process times, being more expensive and time-consuming than the SR one, the SR .

The finite element model is calibrated via compression testing of a range of lattice designs manufactured from powder-bed fusion in 17-4PH stainless steel, and micro-CT imaging assesses any under/oversizing present in the as-built lattice structures. Finally, the lattice design framework is demonstrated by applying the tool to design five . All the samples were tested with a universal testing machine at a rate of 2 mm/min using the ASTM-C365 standard. The results showed that compressive properties are positively related to the relative density and negatively related to the aspect ratio. It was also found that the compressive performance for different materials was in the following .

Six distinct 3D-printed lattice designs with equivalent volume but varying configurations were tested under ambient temperatures of 20 °C, 50 °C, and 100 °C to assess their impact on compressive properties. . a high-temperature uniaxial compression test was carried out on 3D printed lattice-reinforced cement-based composite materials . In the third step, the lattice structure was made using the fused filament fabrication (FFF) 3D printing method, and its compression test was performed. In the fourth step, Poisson's ratio was calculated from the resulting strains using the digital image correlation (DIC) method, and a spot pattern was created on the external surface during the . Uniaxial compression testing was used to characterize and compare the mechanical properties of lattice structures, such as compression curves, compression modulus and strength, and energy absorption capabilities, as well as failure modes. 2. Materials and Methods. 2.1. Materials. Additive manufacturing enables innovative structural design for industrial applications, which allows the fabrication of lattice structures with enhanced mechanical properties, including a high strength-to-relative-density .

This study addresses the mechanical behavior of lattice materials based on flexible thermoplastic polyurethane (TPU) with honeycomb and gyroid architecture fabricated by 3D printing. Tensile, compression, and three-point bending tests were chosen as mechanical testing methods. The honeycomb architecture was found to provide higher values of rigidity .

Download scientific diagram | Lattice compression testing (0.5mm scale bar) from publication: Integrative Design, Build, Test Approach for Biomedical Devices With Lattice Structures | Advances in . This study investigates the effect of printing parameters on the compression properties of hexagonal lattice cylindrical structures (HLCS) manufactured by fused deposition modeling. Polylactic Acid (PLA) was used in producing HLSC. Polylactic Acid (PLA) was used in producing HLSC, and compression tests were performed according to ASTM D695. Wall .

The compression test utilized fixed compression plates as the test fixture. The test rate was set to 0.05 mm/min. The end of the test setting was a load greater than 40%. All 10 mm 3 lattice compression samples were compressed following the print direction (Z-axis).The lattice structure compression test was performed on a universal mechanical testing machine according to the ASTM C365 standard. The loading speed was 2mm/min. . FIG. 2. (a) Compression testing and (b) compression curves of sandwich panels. COMPRESSION ENERGY ABSORPTION 335. densification occur. In this experiment, the plateau stage and

Uniaxial compression tests on lattice structures were conducted using an MTS testing machine at room temperature. All tests were performed at a strain rate of 10 −3 s −1. Fig. 3 (a) . Compression test apparatus; (b) Finite element model with boundary condition. One end of the lattice structure is in contact with and loaded by a moving .

The grayscale histograms of four representatives of lattice structures after compression testing were CT-scanned and reconstructed, and their deformation behavior and pore structure in the internal structure were examined. As shown in Figure 12 a,b, damage was observed in PLA/CaCO 3 10% and PLA/TCP10% cubic strut structures. Some layers were .

Figure 1(a) shows a compression test specimen made out of AlSi10Mg and produced via LPBF. The unit cell of the lattice structure is a rhombic dodecahedron. Similarly to the material test specimens, two sets of lattice structures in as-built and heat treatedstates, respectively, havebeentested. The internal structure of lattice samples after the compression test was scanned and reconstructed by computed tomography (CT equipment, SIEMENS SOMATOM DRIVE, Germany). The CT scan voltage was 70 kV with a current of 61 mA. Each slice thickness was set at 0.5 mm with a slice spacing of 0.3 mm. The field of view (FOV) was 50 mm, and the matrix . Most mechanical testing of SLM lattice structures is performed in compression due to its greater simplicity than testing in tension. This is largely because special design of the sample-test rig interface is required for tensile testing, whereas compressive tests can be more simply performed by crushing a lattice between plates.

Lattice Structures—Mechanical Description with Respect

Resultado da If you have Telegram, you can view and join Belas Trans 🏳️⚧️🔥 right away. right away.

lattice compression testing|Compressive Behaviour of Additively Manufactured